Spray foam, which is also known as Spray Polyurethane Foam (SPF) is a highly durable, long-lasting option that works well with just about any type of existing roofing system. However, some systems, like TPO for example, require additional prep work to ensure proper adhesion.

SPF consists of two separate liquids, isocyanate and polyol. As these are mixed during the spraying process and oxygen becomes involved, they turn into a foam that expands up to 20% of the initial volume.

SPF is well-known for its strong yet lightweight properties, which is vital in reducing structural stress, while maximizing the return on investment for the building owner.

Spray Foam Application Process

Each roof is unique, so this is a simple overview. Your commercial roof may vary slightly in the installation process.

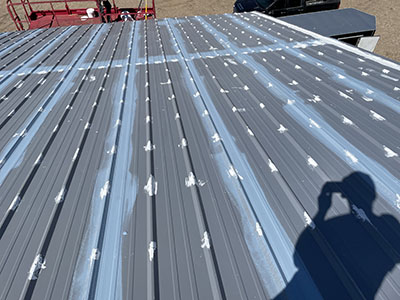

Step 1. The existing roofing surface is prepped for application. This may include minor repairs, addition of prep boards and so forth. Without question, the preparation will include a thorough cleaning. To ensure good adhesion, it is vital the roof surface is clean of dirt, debris, or other contaminants.

Step 2. The isocyanate and polyol are jointly sprayed onto the prepared roofing surface. They mix during the spraying process and are applied at a set rate. This may be the most critical step in the application process. It is vital that a well-trained individual apply the SPF to ensure consistency in both depth and quality, throughout the entire roofing system.

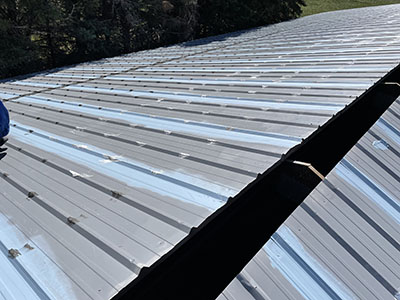

Step 3. Though not always completed, we recommend a highly-reflective coating application on top of the SPF layer. This reflective acrylic coating will reduce solar heat to the roof by up to 85%, resulting in a cooler building overall and reduced cooling costs.

Benefits of Spray Foam

SPF has a LOT of benefits for the commercial building owner.

- Waterproofing. As the liquids combine into a foam, that foam expands up to 20 times the original volume. The foam expands into any existing cracks or defects in the existing system, sealing them tightly.

- Seamless. The entire roofing structure is covered by a single, seamless, monolithic layer of protection. As most leaks occur at the seams or protrusions (think air conditioning vents), this seamless nature virtually eliminates the risk of leaks.

- Insulation. SPF has an R factor up to 6.0 per inch. That means SPF will not only protect the roofing structure, it will also reduce thermal fluctuations within the building. This keeps your employees and customers more comfortable, saves you money on utility bills and even helps reduce the environmental impact of your building by reducing electric or gas consumption.

- Longevity. With proper installation and maintenance, your new SPF roof will last up to 50 years. That is 50 years of cost savings and protection for your building.

- Renewable. Renewability and sustainability are all important now. SPF creates little to no waste. Additionally, none of the components of SPF are environmentally damaging. SPF contains a zero ozone depleting potential, is free of chlorofluorocarbons, has an ultra-low global warming potential and is low in the emission of VOCs.

For more information on spray foam roofing systems or to schedule your no-obligation consultation, please call us today at 641-203-3538. We look forward to meeting with you soon.